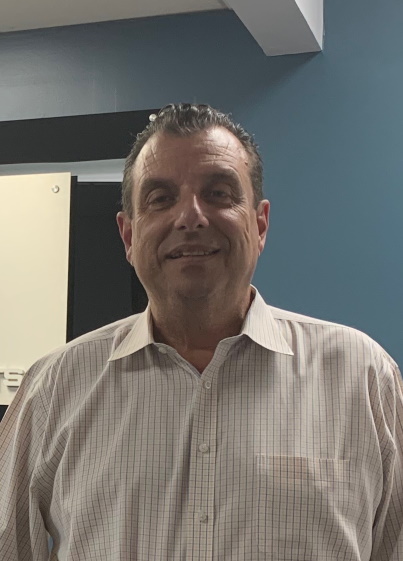

CRB is a global consulting, design and construction services firm specialized in the life sciences industry

. Tom Forester, general manager of CRB Caribe, based in Puerto Rico, shares the developments of the company in the past few years, what makes CRB the partner of choice for life sciences companies and the trends driving Puerto Rico’s economy.

How has CRB Caribe developed since PharmaBoardroom last spoke to you four years ago?

Over the last four years, we have continued to grow consistently year after year and have increased our market share. Moreover, we have experienced very low turnover over this period, which is something I am particularly proud of. Finally, we have invested in the latest 3D design technologies and have trained our talents to become specialists in using it, which has made us stronger. For all these reasons, we have been rated as one of the top companies providing engineering services by Caribbean Business News.

At CRB Caribe, we have always strived to stay in tune with our clients’ culture, standards, and requirements. We learn and adapt to our clients’ culture and do things their way instead of forcing our own. We also make it a point of consistently providing realistic and measurable projections.

One advantage that we have is that we are part of the CRB network. Thanks to our strong processes and communication system we can work on one project remotely from different offices in real-time. This has been incredibly beneficial because it provides support between offices needed to provide the best service possible.

In the life sciences industry, the key to our success lies in our strong focus on helping our customers achieve excellence in regulatory compliance by leveraging Puerto Rico’s long-standing expertise in dealing with the different regulatory agencies worldwide.

Globally, CRB has successfully executed design services for biopharmaceutical projects, including the USD 200 million clinical manufacturing facility for Pfizer in Andover, MA and Takeda’s Plasma Fractionation Facility in Georgia. What have been some of your flagship projects in Puerto Rico?

We have been a reliable partner of biopharmaceutical and medical device companies on the island for many years, and the life sciences industry has been and remains the key driver of our growth.

When it comes to projects, as we are bound by stringent confidentiality agreements, I cannot mention the specifics. One thing I can say is that there are interesting projects coming in fill and finish, in improvements to biopharma active ingredients and even office expansion. Unfortunately, Puerto Rico has not seen greenfield investments in new plants for a while, either in the biopharma and medical device industry, but mostly in expansion and improvement projects.

Moreover, pharmaceutical and medical device companies are investing in energy projects to lower their electrical bill and improving their resiliency by reducing their dependence on the grid. We have worked on many of these projects, such as a combined heat and power plant. We performed a feasibility study for the client showing that they could have their own combined heat and power plant burning natural gas, a very clean fuel compared to what the public power plant burns and save a lot of money while improving reliability. The plant has been running since 2018.

What is your competitive advantage when it comes to meeting the needs of pharmaceutical and medical device manufacturers on the island?

Since we started the business 15 years ago, we have been working in core team mode, meaning that we have one team per pharma company. As a result, we have people who have been working with the same client for fifteen years and are intimately knowledgeable about their facilities, processes and culture. They have become experts and insiders. This is our competitive advantage.

When we met with Rayne Waller, VP Manufacturing at Amgen, he highlighted automation and robotics as two of the most important trends shaping pharma manufacturing. How do you ensure your designs are flexible to accommodate these future technologies?

These new technologies are driven by our clients and we strive to stay aware and in tune with these trends. Our team attends events to continuously learn about pharmaceutical processes and technologies. For example, we have done some work with continuous manufacturing in solid dosage form. Clients are interested in coming and discussing these new technologies with us so we can work together and we stay up to date. Additionally, we work very closely with vendors who are constantly showing us the latest equipment.

When we met with Secretary Manuel Laboy, he highlighted that one of the priorities of the government is to support local service providers and suppliers to large manufacturing companies. Do you think the government is doing enough to support the local ecosystem around pharma manufacturing?

I agree with his approach. One of the reasons why pharmaceutical companies come to manufacture here lies in the strong local ecosystem of capable service providers. The incentive laws have addressed the needs of service providers to ensure that they stay here. Over the years, the laws have been improving. This will positively impact the attractiveness of investments in the biopharma industry.

As representant of the Engineering and Architecture sector at the Puerto Rican Manufacturers Association (PRMA), what are the issues you try and bring to the table?

As a small island in the Caribbean, it is crucial to do everything we can to make Puerto Ric attractive for companies to invest in manufacturing here. I often wonder why so much investment is going to other places and not coming to Puerto Rico. Here in Puerto Rico, we have everything needed: knowledge, infrastructure, US territory and safety. However, nowadays, good projects are going to the Dominican Republic and Costa Rica. The conclusion I have come up with is that it is linked to the overall cost of operations in Puerto Rico. Even though energy cost has been singled out as the main issue because it is high compared to other places, the main problem lies in total cost.

Outside of Puerto Rico, CRB Caribe has been expanding to other markets in the region. What have been some of the success stories abroad?

Our scope includes the Caribbean, Central America, and Mexico. We have performed various projects in Mexico at different moments and nowadays we are working on one in the Dominican Republic. This has been a very interesting project because we have worked in the early stages and will probably work at later stages as well. One thing we aim here at CRB is to always do what is best for our client and sometimes that means having us as consultants or working hand in hand with them.